This article was inspired by Jeremy Smith’s contribution to HVAC School: “Why (and When) Do We Need Defrost?”. HVAC School was founded by Kalos president Bryan Orr and is a free training resource for HVAC and refrigeration professionals across the globe.

If you own or manage a restaurant, supermarket, or convenience store, you’ll know that defrost is a regular part of your refrigeration system operation. Refrigerators must defrost anytime the coils drop below freezing, 32°F.

When the temperatures dip below freezing, any moisture on the coil will freeze. As that water freezes, it forms layers of ice on the coils. Those layers of ice prevent the refrigerant in the system from absorbing heat inside the fridge. As a result, the refrigerator will have a harder time keeping products cool. You may end up with food spoilage, which may negatively affect profits and present food safety hazards.

Defrost can be as simple as shutting the compressor off for a while. It can also involve complicated procedures like reversing the refrigerant flow to send hot gas through the coils. We’ll cover these different methods and the controls that manage the defrosting process.

Table of Contents

DEFROST METHODS

In the olden days, we used to take everything out of the refrigerator and unplug it. We’d have to wait for several hours for the ice to melt, or we’d speed up the process with a makeshift ice pick (whether that be a screwdriver or a piece of cutlery) or a hairdryer.

Of course, those methods are wildly impractical for commercial refrigerators. Nowadays, we have much more efficient ways of defrosting refrigeration systems.

Off-Cycle Defrost

The off-cycle defrost is the simplest and most common method of all. As its name suggests, this method turns the system off and naturally lets the ice melt off the coil. When the system turns off or pumps down, the evaporator fans keep running, which forces the system to defrost.

The off-cycle defrost is only practical on smaller medium-temperature coolers, as the air needs to be above 32°F. So, you will most commonly see off-cycle defrost on coolers for produce and beverages, as those should never freeze.

Electric Defrost

Remember when I said that some people used to use hairdryers to defrost their home refrigerators? The same principle is at play with electric defrost; we use electric heat to melt the ice off the coils.

As with off-cycle defrost, electric defrost relies on timers and other similar controls to signal when to start and stop the process.

Although electric defrost is effective on a wide range of equipment, it is a long and slow process. Applying external heat is much less effective than using internal heat to melt the coils (as with hot gas defrost). So, it can take a long time to heat those coils and expend a lot of energy. On top of that, you may only get a partial defrost from electric heat. Partial defrosts leave some ice and moisture on the coil, making the refrigerator more prone to refreezing.

Hot Gas Defrost

The final common method uses hot gas within the system to heat the coils from the inside. A valve de-energizes and creates a pressure differential; that pressure differential reverses the flow of hot discharge gas and sends it to the evaporator. The system has two actuating valves that help control the flow direction, and the discharge gas behaves as it does in heat pump applications. Since discharge gas may exceed 200°F, it can melt ice off the coil with relative ease. Most supermarket refrigerators will use this method.

Hot gas defrost control strategies are expensive to install, but the method's quality and versatility typically help offset the price. Discharge gas runs through the entire coil and does a better job of reaching the entire coil than external electric heat.

As with electric defrost, the hot gas method requires the fan to be off during and after the defrosting procedure.

CONTROL STRATEGIES

All of those methods would be a real pain for us to control on our own. With so much product and profits at stake, remembering the exact time parameters would put a lot of pressure on us.

Luckily, we can rely on plenty of control strategies to automate the defrosting process.

Cold Controls (Constant Cut-In)

One of the most common controls is the automatic cold control, also known as the constant cut-in.

These controls have sensing bulbs in the evaporator that pick up the temperature. The controls refer to a fixed cut-in point and an adjustable cut-out point; the cut-in temperature is above freezing, usually in the upper 30s, and the cut-out temperature may be as low as around 10°F.

When the bulb senses that the system has reached the fixed cut-in point, the control closes and turns the compressor on. Later, the control opens when the bulb detects that the evaporator temperature has reached the cut-out point. The compressor turns off and remains inactive until the bulb senses that the system has reached the cut-in temperature again.

The logic behind cold controls is that they will stop the compressor after frost has had some time to accumulate on the coils. They will only turn the system on again if the freezing conditions are no longer present.

Defrost Timers

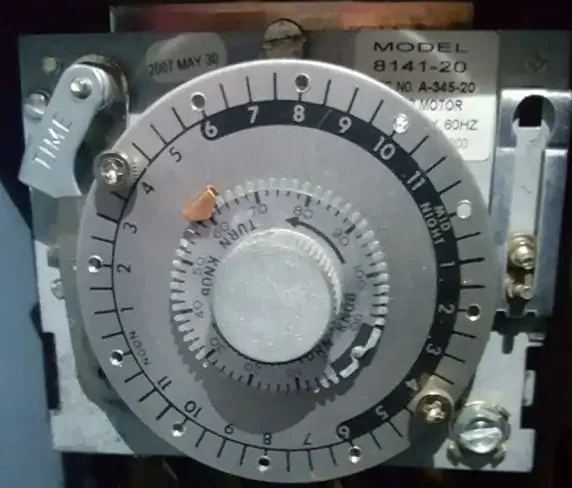

We use timers in medium-temperature applications to help us manage off-cycle defrosts. Timers help us determine when our refrigerators shut off and for how long.

A cold control only activates whenever the sensor relays a signal for the control to open or close, making it unpredictable. Defrost timers allow us to control the defrost parameters directly instead of relying on sensors to send signals to the circuit board.

We may also use timers with the other two defrost types, electric and hot gas. However, these applications are a bit more complicated.

Defrost termination on electric and hot gas defrosts requires a failsafe and a fan delay.

Defrost Termination Thermostat and Failsafe

Termination is critical on electrical or hot gas defrost systems. While we want to ensure that the coil is completely ice-free, defrosting strategies use up a lot of energy and may overheat the coil; we want to stop the defrost process before the coil gets too hot.

On systems that use electricity or hot gas for defrosting the coil, there will typically be a defrost termination thermostat. This device senses when the coil is free of ice and stops the defrost. In other cases, the thermostat stops the defrosting process when the coil reaches 55-60°F to ensure that the coil has no ice whatsoever.

On rare occasions, the termination thermostat may malfunction and fail to terminate defrost. In those cases, we could face severe product losses. To avert that crisis, the failsafe steps in to stop the defrost after a set amount of time. The failsafe time is the maximum amount of time that a system will stay in defrost; it will often be in the 20-40-minute range.

When the termination thermostat kicks in, the system resumes normal operation. However, the fans shouldn't turn on until the coils have had some time to drain. If the fans were to turn on immediately, they'd blow melted ice all over the place. You'd get a gross, slushy mess in the refrigerated box if that were allowed to happen. So, these applications have a fan delay. The fan delay prevents the fan from starting until a certain coil temperature is reached, usually around 30°F. The logic is that the refrigerator will have had some time to drain all of the melted moisture by the time it cools back down to the set temperature.

As you can see, each defrost method has its advantages, drawbacks, and appropriate uses. The same is true of the control strategies. Nevertheless, each method and control helps protect perishable products in supermarkets, restaurants, and other food sale or preparation facilities.

For more information on the causes and prevention of frozen cases, check out our article on the subject.