To be clear, it’s a good thing when the insides of refrigeration cases are cold. It’s not good when ice builds up inside them or when their piping freezes over. Some degree of freezing will happen naturally, but proper defrost cycles should take care of it. When evaporator coils stay frozen over for a long time and can’t defrost properly, the refrigerator cases won’t be able to cool as they should.

When the liquid refrigerant enters the evaporator coils, it absorbs heat from the environment. It’s tough for the refrigerant to absorb heat when the coils are covered in thick layers of ice. Food may spoil if the refrigerator can’t keep the surroundings cool.

Retail managers may want to know what they can do to prevent or fix frozen cases in their stores. Luckily for them, there are some steps they can take to help prevent their cases from freezing. I’ve spoken to Nathan Orr to help talk about frozen cases, control strategies for retail managers, and defrosting. Nathan Orr leads the Kalos Services heavy mechanical division. He is also the VP and a co-owner of the company.

Table of Contents

Freezing causes

Based on the service calls that we receive, we see four leading causes of freezing. Your refrigerator may freeze due to one or a combination of the following situations.

Poor airflow

One culprit of freezing is poor airflow across the evaporator coils. The causes of low airflow are the same as in air conditioning, such as broken blower motors or dirty evaporator coils.

Evaporator coils can become insulated with grime, which hinders airflow and makes it harder for the refrigerant to remove heat from the environment. When the refrigerant can’t absorb heat properly, it may stay too cold, and the water moisture along the coils may freeze.

Improper drainage

Another common cause is that water drainage can’t properly escape. Condensate drains remove water moisture from the area around the evaporator coils. When the drains can’t do their job, the condensate stays and may freeze.

Defrosting issues

Issues with your defrost cycles may also cause the coils to freeze. Defrosting is the process that melts the frost from the coils, whether that means turning the system off for 25-45 minutes or using electrical or gas defrosting methods. Freezing may occur when the defrost cycles are too short. Electrical defrost controls may also develop mechanical issues that lead to freezing.

Frozen environmental conditions

One of the most frequent causes of frozen refrigerator cases is cold environmental conditions.

When you leave a walk-in or swinging glass door refrigerator open, humid outside air enters the case. When you let moist air get into the refrigerated space, you allow moisture to accumulate. That moisture will then freeze on your equipment.

I’ve found a frozen case in my store. What can I do?

While checking up on your units, you notice that the evaporator coils have frozen over. As a facilities manager, what can you do?

First, you should see just how much frost is on the coils. If it’s a small amount, then there’s a strong chance that you won’t need to do anything. A little bit of frost will always form on the coils, and a proper defrost cycle should take care of it.

But what if there’s a heavy ice buildup? That’s when you should call a service technician. You can’t do much to solve the problem on your own.

However, there are some things you can do to make it easier for the techs to solve your problem. Before you call a technician, there are two things you can do.

The first thing you can do is take pictures of the freezing. That way, the service technician can see exactly what you saw, and they may diagnose and solve the issue more easily.

The second thing you can do is turn off the circuit. Some units have a hand valve that you can turn to power the circuit off.

Again, these aren’t required, but your service technicians will appreciate you if you can take these basic steps to make their jobs easier.

What can I do to prevent frozen cases?

There is one main prevention method for frozen cases. (It will also make your service techs will love you.)

Keep the refrigerator doors closed whenever possible.

That’s it. Just keep the doors closed whenever you can. When people keep the doors open too much and cause the case to freeze, they usually won’t know what caused the issue and make a service call without a specific issue. The technicians will test every element of the refrigerated system, and then they’ll conclude that the doors were left open too long. Prevention is the only cure, so those service calls are a waste of time for everyone.

Now, we understand that it will be difficult to control the glass doors on the sales floor. Some customers keep the doors wide open while they figure out which ice cream flavor they want. That’s uncontrollable, and technicians typically understand that challenge. However, you can still reduce the probability of frozen coils on your other refrigerators if you can keep those doors closed whenever you’re not actively stocking or removing product.

Electric vs. gas defrost

An article on frost prevention wouldn’t be complete without a quick overview of defrosting methods. We’re going to discuss the differences between electric and gas defrost.

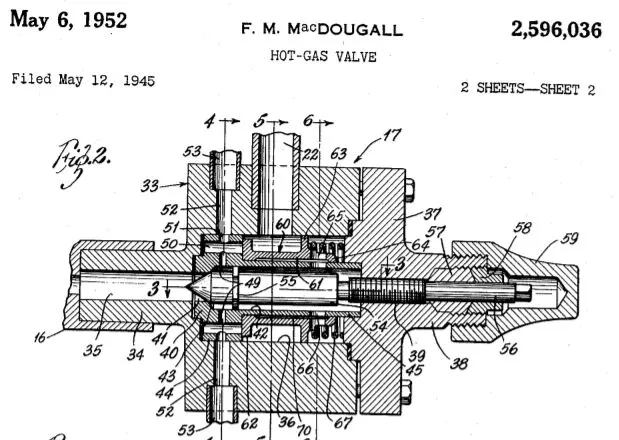

Electric defrost uses an electric device to defrost the system. (They're like giant hairdryers.) Gas defrost uses energy within the system to defrost, usually by reversing the refrigeration cycle via a valve. (The image above shows a gas defrost valve.) The hot, high-pressure vapor that usually goes to the condenser after compression goes to the evaporator, and the heat melts the ice on the coils. As a result, the gas defrost process is quite rapid.

Conversely, electric defrost is long and slow. It takes a long time for the external heat to warm the coils, possibly resulting in partial defrost. Partial defrost is undesirable and may lead to frost buildup and freezing over time.

However, gas defrost isn’t perfect either. Because the process is so fast, you may end up steaming water near the coils. That isn’t a terrible thing, but it may look alarming. The main downside is that gas defrost may overheat the case if it lasts too long. Case overheating may lead to food spoilage or decreased food quality, negatively affecting profits and customer satisfaction.

When you oversee market refrigeration practices, you’re bound to see freezing at some point. Even though there isn’t much that you can do about it as a manager, there’s no need to panic. At Kalos, our technicians are well equipped to troubleshoot freezing, whether that means replacing a blower motor, checking the defrost controls, or advising you to keep the doors closed more often. It’s still good to know what causes freezing and how you can prevent it to the best of your abilities.