Refrigerant is the name of the fluid inside an HVAC or refrigeration system. Some people call it “Freon,” which is actually a brand name for a specific manufacturer. (It's like how we call bandages “Band-Aids” or gelatin “Jello.”) That refrigerant cycles through the system over and over, which can make us wonder if it can ever go bad, get used up, or wear out. The truth is that refrigerant doesn't wear out, go bad, or need refills in a leak-free system. Our cars need oil changes every now and then because the oil gets dirty and breaks down over time, but refrigerant doesn't work that way.

Sometimes, technicians have to add refrigerant, but it's usually not because the refrigerant “goes bad” inside the system. Refrigerant doesn't typically “wear out” in the way that we might imagine. However, blended refrigerants can cause a drop in performance when their mix becomes uneven. This article will explain why refrigerant doesn't “go bad” as we might imagine, how blended refrigerants can “go bad,” and why we might need to add refrigerant to a system.

HOW REFRIGERANT WORKS

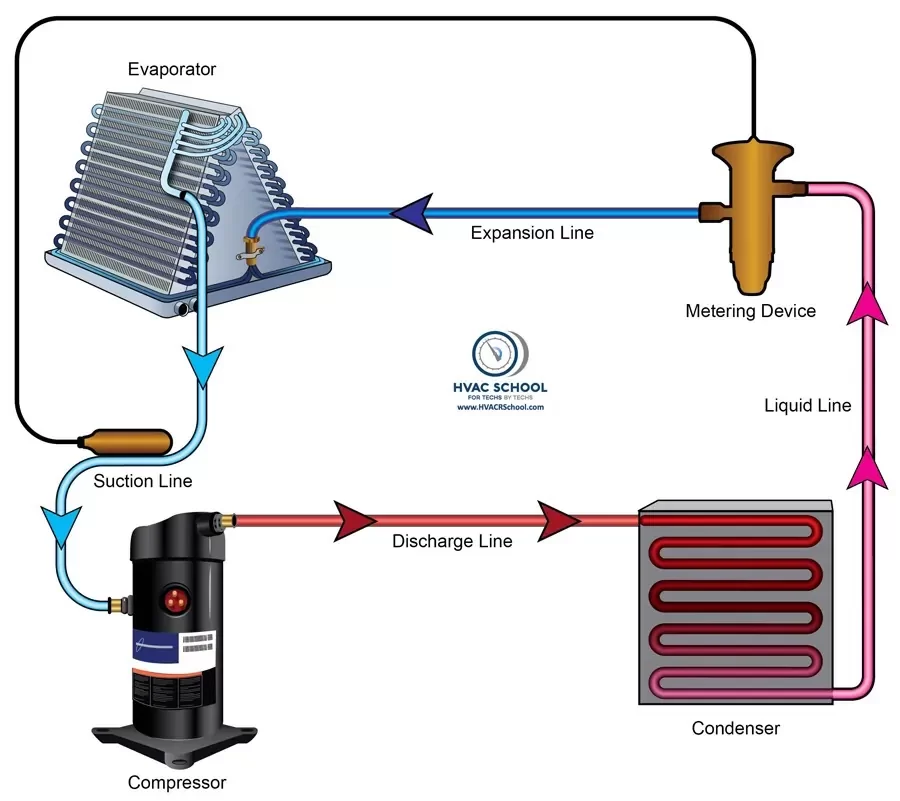

A/C and refrigeration systems absorb heat and reject it somewhere else.

Inside the air handler of an A/C unit, cold liquid refrigerant moves through the evaporator coil. The blower moves air over the coil. Since the air is warmer than the refrigerant, it loses some of its heat to the refrigerant. As the refrigerant absorbs that heat, it boils; the fluids used in A/C and refrigeration systems have much lower boiling points than water. The refrigerant is under pressure in an HVAC system, so the boiling point is typically around 40 degrees Fahrenheit in a typical residential A/C unit. (However, at atmospheric pressure, R-410A has a boiling point below -55 degrees Fahrenheit!)

Once it has boiled off, the now-vapor refrigerant moves to the compressor, where it is squeezed into a smaller volume and gets a lot hotter. The discharged vapor then moves to the outdoor unit, where the outdoor temperature is far lower than the vapor temperature. A fan blows over the coil, and the hot vapor loses some of its heat to the cooler air. As it loses heat, it becomes a liquid again.

After the refrigerant becomes a liquid, it returns to the indoor unit and undergoes a pressure drop before repeating the cycle at the evaporator coil.

The refrigerant does that over and over, and it doesn't wear out in the process. It simply changes from liquid to vapor and back again as it absorbs and rejects heat.

Grocery refrigeration systems work similarly; evaporators absorb heat from inside the refrigerated boxes, and the condenser rejects that heat outside. There are usually many compressors, and the refrigeration cycle takes place with the help of large racks that can control multiple evaporators and compressors.

WHY MIGHT I NEED TO ADD REFRIGERANT?

Refrigerant doesn't wear out, but it can leak at fittings, valves, or through pinhole leaks in the copper or aluminum. Leaks are likely when a joint or valve has been poorly brazed in. Corrosion on the evaporator coil or line sets can also cause pinhole leaks.

Many leaks are usually very slow, but they negatively impact your equipment's ability to remove heat. A smaller volume of liquid in the evaporator coil won't be able to absorb as much heat as a larger amount. The smaller volume will also heat up more than a larger volume, and it may lead to overheating in the compressor as well.

So, we can add more refrigerant in the short term. Even though the production of R-22 was banned in 2020, it is still legal to add R-22 to older systems. However, recharging the system can be very costly due to the lack of newly produced stock.

A long-term solution would be to replace the leaking components, which could be a line set, valve, or even an evaporator coil. An HVAC technician should do thorough leak detection and pinpoint the location of a leak before offering to replace a leaky component.

However, significant leaks can cause even more trouble in systems that use blended refrigerants.

WHAT CAN HAPPEN TO BLENDED REFRIGERANTS?

Some blended refrigerants can “go bad,” but it's not in the way we think they can.

R-410A is an example of a refrigerant blend. R-410A uses R-32, which is a good refrigerant but is flammable. To temper the refrigerant's flammability, manufacturers mix R-32 with R-125, which is a flame suppressant. The R-410A example goes to show that whenever you mix refrigerants, you mix chemicals with different properties.

Those different properties cause those refrigerants to have “glide,” which is a range of boiling points based on all refrigerants in the mixture. R-410A has very little glide, but refrigerants like R-407C have significant glide. R-407C consists of R-32, R-125, and R-134A. When there is a leak, the higher-pressure refrigerants leak out faster than the others in the mixture. The uneven losses cause “fractionation,” which causes the refrigerant's chemical makeup to change, leading to swings in temperature and pressure. Those dramatic swings can cause poor performance.

For that reason, technicians must add blended refrigerants to HVAC systems in the liquid state (not vapor). HVAC technicians must also check tanks and systems for leaks. A significant leak in an HVAC or refrigeration system may cause fractionation, but even small leaks can alter the chemical makeup of refrigerants stored in upright tanks.

If there is a reason to suspect that fractionation has occurred inside a system, it's typically best to have an HVAC technician recover all of the remaining refrigerant in the system. Then, the technician would charge the system with brand new refrigerant (and make sure to add it in the liquid state).

Pure refrigerants (like R-22 and R-32) simply won't wear out. They can deplete if there are leaks, but they don't stop working. The same is somewhat true (but more complicated) for blends; the refrigerant doesn't completely stop working, but the fractionation caused by leaks may cause a performance decline.

All of this is to say that refrigerants don't get dirty and break down like car oil. Refrigerants can do the same job over and over again for several years at a time. Leaks are often the culprits of performance concerns, not the refrigerant “wearing out” or “going bad.” That said, if you notice a decline in your system's performance, it's a good idea to contact an HVAC/R professional to find out if any leaks or other potential issues are causing your HVAC/R system to perform poorly.