Let’s say you put hot food, livestock carcasses, or other warm products in an ordinary freezer. You’ll probably notice that it takes a long time for those warm things to freeze. Although it may be annoying, it's normal for warm products to take an eternity to freeze. We call the act of freezing warm products “hot pull down.” However, even though a hot pull down is normal, it isn't good for your refrigerator.

Most refrigerators are simply not made for chilling food to freezing temperatures in a short span of time. Some fast-food restaurants use “flash freezers” that can bring warm products down to a freezing temperature. “Blast chillers” serve a similar purpose. However, many restaurants, grocery stores, and small farming operations lack flash-freezing equipment. Those businesses will likely have to consider the possibility of hot pull downs.

Table of Contents

WHAT IS A HOT PULL DOWN?

“Hot pull down” refers to a condition in which the refrigerator has difficulty removing heat from the box. The phenomenon is due to the box having a much higher heat load than normal. You will most often see hot pull downs on startup after a long time of non-operation or when loading the box with hot food.

Most refrigerators are designed to maintain a product’s temperature or bring it down slowly, not bring it down to below-freezing temperatures in a snap. Many people will not deal with a “hot pull down” if they freeze foods that were already frozen from the market or wholesaler. Leftovers from the medium-temperature fridge likely won't cause a hot pull down if they move to the freezer; they have already had their temperature brought down, and that temperature will continue to fall slowly.

However, hot pull downs can be a problem if you're dealing with warm, really fresh products, like those chickens in the image above. For example, a small-time or self-sustaining chicken farmer may need to store chicken carcasses after slaughtering and cleaning them. Many large-scale meat storage facilities have chillers that can rapidly reduce temperatures, but many smaller farmers don't have those and may only have a commercial refrigerator at best. Those freshly-slain chickens had body temperatures exceeding 100°F, so it will be tough for the refrigerator to pull the carcasses down to a safe temperature at once. (A safe temperature for meat storage should not exceed 40°F! Read more about food safety guidelines HERE.)

WHY IS IT DIFFICULT TO PULL THE TEMPERATURE DOWN?

The cooling ability of a refrigerator depends on two main design factors: capacity and coil-feeding range.

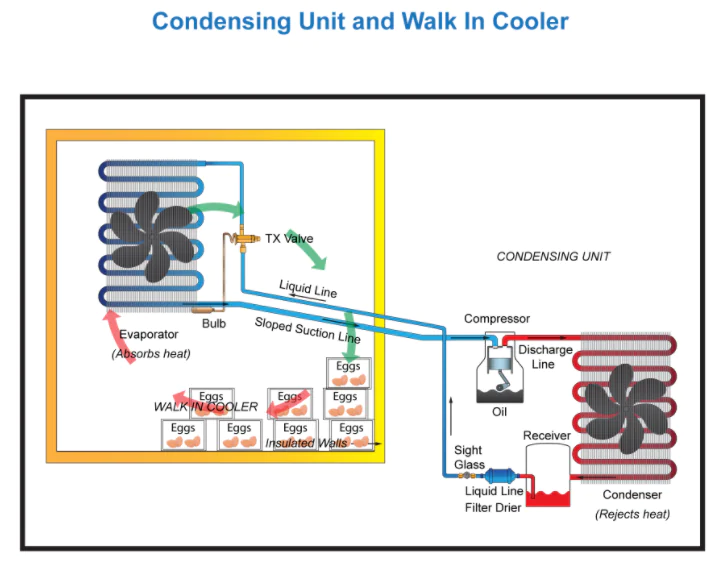

Capacity refers to the ability of a cooling system to remove the most heat over time. As with A/C systems, refrigerators use refrigerant (“Freon”) to absorb heat and carry it away from the conditioned space. In the case of a refrigerator, that “conditioned space” is the refrigerator box. A refrigerator that has a hard time with hot pull downs may not have enough refrigerant in it to absorb heat from the box quickly enough, even if it has the appropriate amount of refrigerant for the system design.

The coil-feeding range refers to the metering device’s ability to feed low-pressure refrigerant into the evaporator coil. Metering devices, such as the TX valve in the picture above, reduce the pressure of the refrigerant before feeding it into the evaporator. In the case of a hot pull down, the evaporator coil starves because the metering device can’t feed it with enough refrigerant to handle the heat load. That refrigerant will exit the evaporator at a very high temperature, making it unable to cool the compressor and likely to overheat it.

In short, the refrigerator simply doesn’t have enough refrigerant to handle such a sudden, intense heat load. So, the fridge struggles to bring the product temperature down at best and could suffer compressor damage at worst.

WHAT SHOULD I DO TO PREVENT A HOT PULL DOWN?

Keeping the box temperature low is the key to preventing a hot pull down.

The best thing you can do is wait for food to cool down before you stuff it in the refrigerator. That way, you lessen the heat load inside the box when the food goes in. When your refrigerator isn't straining to regulate temperature, you decrease your likelihood of compressor failure.

You can also prevent the box temperature from rising if you ensure that there is good circulation inside. Ensure that there is adequate spacing between all the products in the box. When air circulates better, the products don't retain heat as much, and the refrigerator is more effective at keeping the box (and food) cool.