Our Updates

Air Conditioning Content

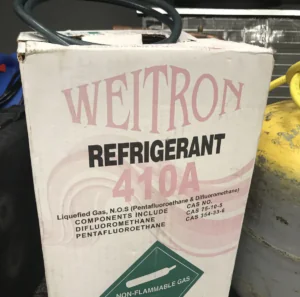

What’s up with “Flammable” Freon (A2L Refrigerant)?

HVAC systems contain a fluid called refrigerant (which some people call by the brand name

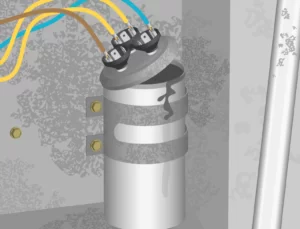

Why Do Capacitors Fail?

Some of the parts that fail the most often, especially in the summer, are run

Why Do Ducts and Air Handlers Sweat in the Attic?

If you've ever gone into the attic and seen your ducts covered in water, you

Does Refrigerant Go Bad or Wear Out?

Refrigerant is the name of the fluid inside an HVAC or refrigeration system. Some people

Manage Indoor Pollution

The average person inhales approximately 3000 gallons of air per day over the course of

Maintenance for Ductless Mini-Splits

Ductless mini-splits are popular A/C systems in many of the communities we serve. Many of

What Air Filter is the Best?

Some of the most common questions we hear our customers ask are: “Which air filter

What is a Ductless Mini-Split?

You may have gone over to a friend's house or spent some time in their

What is a Leaky HVAC System?

If your A/C unit hasn't been running as well as it usually does, you may

DIY Drain Cleaning Dos and Don’ts

One of the most common issues we see on residential and light commercial A/C units

R-410A Phase-Down: What Consumers Need to Know

You may already know that your A/C unit requires “Freon” to work. “Freon” is an

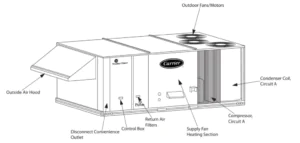

What Happens on a Commercial Package Unit PM?

Preventive maintenance is crucial for commercial HVAC equipment. Those units have so many moving parts